Semiconductor Manufacturing Is (Now) American Manufacturing

American manufacturing has long been a cornerstone of the nation’s economy, driving innovation, providing jobs, and ensuring economic stability. From the early days of the Industrial Revolution to the present, manufacturing has played a critical role in shaping the country’s industrial landscape. Manufacturing in America is not just about producing goods; it’s about fostering a robust economic ecosystem that supports millions of families, communities, and businesses.

Semiconductors are critical components in modern electronic devices, enabling advancements across various industries and highlighting the growing demand for these devices.

In recent years, the importance of revitalizing American manufacturing has gained renewed attention. With global supply chain disruptions and increasing competition from abroad, there is a strong push to bring more manufacturing operations back to U.S. soil. Whitehouse.gov reports 642,000 manufacturing jobs have been created since 2021 after the federal government’s initiatives to increase the industry.

Recognizing the strategic importance of manufacturing, the U.S. government has introduced various initiatives and policies aimed at bolstering the sector. Programs such as the CHIPS Act, which focuses on boosting domestic semiconductor production, and the Advanced Manufacturing Partnership, aim to enhance the competitiveness of American manufacturing on the global stage.

In this blog post, we’ll delve deeper into the specific area of semiconductor manufacturing projects, exploring their importance, current state, and economic impact, and demonstrating how BuildCentral can help you find and capitalize on these opportunities.

Related: Infrastructure Bill: Where’s the Money Going?

Focus on Semiconductor Manufacturing Projects

The semiconductor manufacturing process is a complex and critical series of steps, from initial design to final production, that ensures the efficiency and reliability of semiconductor products.

What are Semiconductors?

Semiconductors are materials that have a conductivity between conductors (usually metals) and nonconductors or insulators (such as most ceramics). They are the essential building blocks of modern electronics, forming the basis for the integrated circuits used in everything from smartphones and computers to cars and industrial machinery. Semiconductor devices are constructed using highly pure silicon wafers through a series of complex and precise steps, aiming to produce advanced electronic components like integrated circuits. Made from silicon, germanium, or other materials, semiconductors have unique electrical properties that allow them to control the flow of electricity in devices, making them integral to the functionality of a wide array of electronic equipment.

Importance of Semiconductors and Domestic Semiconductor Manufacturing Process

The importance of semiconductors cannot be overstated. These tiny components are at the heart of nearly every electronic device we use today. They power our smartphones, data centers, enable our computers to process information, and allow our cars to have advanced safety and navigation systems. Semiconductors are also critical for emerging technologies such as artificial intelligence, 5G communications, and the Internet of Things (IoT), all of which rely heavily on advanced semiconductor technology. Big Tech wouldn’t exist without semiconductors.

A semiconductor device is manufactured through a complex process known as semiconductor device fabrication, which involves multiple steps to create integrated circuits. This process requires specialized facilities and stringent control of environmental conditions to enhance production yield.

In addition to their technological significance, semiconductors are crucial for national security. Many advanced defense systems, from radar and communications to weapons systems, depend on sophisticated semiconductor components. Ensuring a reliable and secure supply of semiconductors is therefore a strategic priority for the United States.

Current State of Semiconductor Manufacturing in the U.S.

The U.S. semiconductor manufacturing industry has been facing several challenges in recent years. Despite being a global leader in semiconductor design and innovation, much of the actual manufacturing has been outsourced to countries in Asia, particularly Taiwan and South Korea. This outsourcing has led to vulnerabilities in the supply chain, as seen during recent global chip shortages.

Semiconductor manufacturing equipment plays a critical role in the industry, being essential for the fabrication process and ensuring product quality and effective manufacturing.

To address these challenges, significant efforts are underway to boost domestic semiconductor manufacturing. The CHIPS Act, passed in 2021, is a landmark piece of legislation aimed at revitalizing the U.S. semiconductor industry. It provides $52 billion in funding to support the construction and expansion of semiconductor manufacturing facilities in the U.S. Major companies such as Intel, TSMC, and Samsung have announced plans to build new fabrication plants in the United States, with projects underway in states like Arizona, Texas, and New York.

Economic Impact of Semiconductor Manufacturing Facilities

The economic impact of semiconductor manufacturing facilities is substantial, contributing significantly to local and global economies. These facilities require a highly skilled workforce, advanced technology, and substantial capital investment.

A critical component in this process is the silicon wafer, which serves as the foundational material from which microchips are created. The complex processes involved in shaping and preparing the silicon wafer lead to the deposition of various materials essential for chip formation.

Semiconductor Manufacturing Equipment Job Creation and Workforce Development

One of the most significant benefits of constructing semiconductor manufacturing facilities in the U.S. is the creation of high-quality jobs. These facilities require a diverse workforce, including engineers, technicians, construction workers, and maintenance staff. The demand for skilled labor in fields such as electrical engineering, materials science, and computer science will lead to extensive job creation, providing new opportunities for American workers. Whitehouse.gov even reports that semiconductor employment has increased an average of 4.3% since 2021.

The semiconductor manufacturing process is a complex and crucial series of steps, including photoresist coating and assembly, which require stringent quality control to ensure product quality and efficiency.

Moreover, the development of these facilities often comes with investments in education and training programs. Partnerships between semiconductor companies and educational institutions can lead to the creation of specialized training programs, apprenticeships, and internships, ensuring that the workforce is well-equipped with the necessary skills. This focus on workforce development not only supports the semiconductor industry but also strengthens the broader manufacturing sector by fostering a pipeline of skilled labor.

Related: Infrastructure Project Data: Your Key to More Business.

Semiconductor Manufacturing Boosts Local Economies

The construction and operation of semiconductor manufacturing facilities have a profound impact on local economies. These projects involve significant capital investments, often amounting to billions of dollars. The influx of investment spurs economic activity in the surrounding areas, benefiting local businesses and suppliers. Construction phases create demand for materials, equipment, and services, while the ongoing operations of the facilities generate continuous economic benefits through employment and local spending.

A critical component in the semiconductor manufacturing process is silicon wafers, which serve as the foundational material for chip fabrication. Advanced technologies are employed to produce high-quality silicon wafers, enhancing their semiconducting properties and suitability for intricate circuitry.

Semiconductor Manufacturing Critical to Global Competition

Strengthening the domestic semiconductor manufacturing industry is critical for maintaining and enhancing the U.S.’s global competitiveness. The ability to produce semiconductors domestically reduces dependence on foreign suppliers, mitigates risks associated with supply chain disruptions, and ensures that the U.S. can meet its own needs for critical technologies. Thin films play a crucial role in the fabrication of microchip structures, where various materials are deposited onto silicon wafers to create the different layers necessary for building complex microchip designs. This strategic advantage is essential for maintaining leadership in key industries such as technology, defense, and telecommunications.

Overall, the construction of semiconductor manufacturing facilities is a catalyst for economic growth, job creation, and global competitiveness, providing substantial benefits to the U.S. economy and its position on the world stage.

How BuildCentral Helps You Find Semiconductor Manufacturing Projects

BuildCentral helps you find semiconductor manufacturing projects by providing detailed information on upcoming and ongoing projects. This includes data on project stages, key contacts, and equipment needs.

In semiconductor manufacturing, wet etching is a crucial process that involves using chemical baths to wash the wafer, revealing desired patterns without damaging underlying layers. Precise control in etching processes is essential as chip designs become more complex.

Comprehensive Project Database of Semiconductor Manufacturing Projects

BuildCentral offers an extensive and detailed database of construction projects, including those focused on semiconductor manufacturing. Our database is regularly updated to ensure you have access to the most current information on upcoming and ongoing projects. The database includes critical details such as project locations, timelines, budgets, and key stakeholders, providing a comprehensive view of each project.

One critical process in semiconductor manufacturing is ion implantation, where charged ions are embedded into silicon wafers to modify their electrical properties. This technique is essential for creating micro-transistors and ensuring the silicon can effectively conduct electricity, allowing for the fabrication of integrated circuits.

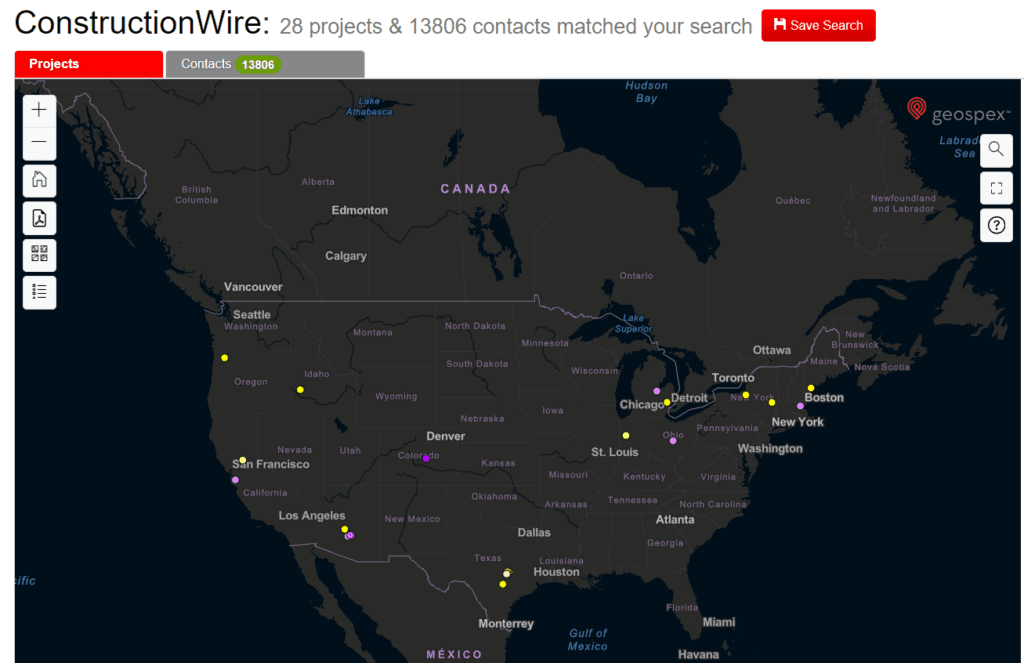

GEOSPEX™ Map and Location Analytics

Our GEOSPEX™ map combines planned real estate development data with GIS (Geographic Information System) data layers to provide new insights into a market’s growth opportunities and potential risks. Use our map to easily see project estimates, a heatmap, cluster map, and drawing layers. Visualize upcoming projects with our innovative map.

Tailored Project Leads

One of BuildCentral’s standout features is its ability to provide tailored project leads. By setting up customized alerts, you can receive notifications about new projects that match their specific interests and business needs. These alerts are designed to keep you informed about the latest developments in the semiconductor manufacturing sector, ensuring you never miss a valuable opportunity.

Related: How to Get Construction Leads.

Networking and Opportunities

BuildCentral not only helps users find projects but also facilitates connections with key decision-makers and stakeholders involved in these projects. The platform provides contact information for project managers, developers, contractors, and other relevant parties, enabling users to establish direct communication channels. This can lead to valuable partnerships and collaborations, opening doors to new business opportunities.

Get started with a free trial to find the right projects for your business.

Examples of Semiconductor Manufacturing Projects on BuildCentral

We’re tracking 28 planned or under-construction semiconductor manufacturing projects and nearly 14,000 associated contacts across the US.

Taiwan Semiconductor Manufacturing Company

| Project Type/Size: | Mfg./Industrial/Warehouse (250,000+ sq-ft) |

| Construction Type: | New |

| Estimated Value: | $6600 million |

| Sector: | Private |

| Location: | Phoenix, AZ 85083. 5088 W Innovation Cir |

| Details: | Plans call for the construction of a new semiconductor fabrication plant for Taiwan Semiconductor Manufacturing Company as part of its expansion. |

| Stage: | Planning |

The TSMC Phoenix semiconductor manufacturing facility, under construction.

Maruichi Stainless Tube Texas Corporation Manufacturing Facility

| Project Type/Size: | Mfg./Industrial/Warehouse (125,000 sq-ft) |

| Construction Type: | New |

| Estimated Value: | $5-$25 million |

| Sector: | Private |

| Location: | Seguin, TX 78155. 107 E 7th Ave |

| Details: | Plans call for construction of a new 125,000 square-foot semiconductor manufacturing facility on a 33-acre site. |

| Stage: | Planning |

Micron Chip Manufacturing Factory

| Project Type/Size: | Mfg./Industrial/Warehouse (250,000+ sq-ft) |

| Construction Type: | New |

| Estimated Value: | $100 billion |

| Sector: | Private |

| Location: | Clay, NY 13041. Caughednoy Rd and NY 31 |

| Details: | Plans call for construction of a new chip factory with four semiconductor fabrication plants (fabs) for Micron Technology, Inc. |

| Stage: | Planning |

Recap of the Importance of American Semiconductor Manufacturing

American manufacturing, with its rich history and substantial impact on the economy, remains a critical component of the nation’s industrial strength. The focus on revitalizing this sector, particularly through government investments and initiatives, underscores its importance in job creation, economic stability, and technological innovation. Semiconductor manufacturing, a cornerstone of modern technology, exemplifies the potential of American manufacturing to drive economic growth and enhance global competitiveness.

Related: Upcoming Manufacturing Projects in Ohio.

BuildCentral Has All the Data You Need to Find Manufacturing Projects

BuildCentral plays an essential role in this revitalization by providing invaluable resources to businesses looking to engage with semiconductor manufacturing projects. With its comprehensive project database, tailored project leads, and networking opportunities, BuildCentral ensures that companies have the information and connections they need to succeed. By leveraging BuildCentral’s tools and insights, businesses can stay ahead of industry trends, identify lucrative opportunities, and establish themselves as key players in the semiconductor manufacturing sector.

Start your free trial to find semiconductor and other manufacturing project details, location analytics, and decision-maker contact details.