How AI and 3D Printing Are Accelerating Construction Project Timelines

We’re living through an exhilarating time in construction, where digital tools and robotics are not only making the industry smarter—they’re fundamentally changing what’s possible, from the drawing board to the jobsite. Two of the most impactful technologies setting a new pace are artificial intelligence (AI) and 3D printing. Together, they’re helping us and our partners across the construction landscape slash project timelines, minimize bottlenecks, and reshape how we think about building itself.

The Roadblocks: Why Construction Timelines Lag

Even as new materials and software emerge, traditional construction projects are still slowed by issues that feel all too familiar:

- Weather disruptions and supply chain hiccups, often stalling progress unexpectedly.

- Manual paperwork, takeoffs, and project coordination eat up hours (and absorb teams’ energy).

- Rigid schedules don’t reflect the rapid adjustments needed when delays or resource clashes occur.

- Layers of approvals and documentation, often slowing down the go-ahead for each phase.

For us, helping clients get ahead of these hurdles starts with understanding where new technology can deliver time back—and where careful integration can mean the difference between marginal improvement and transformative acceleration.

AI in Preconstruction: Compressing Analysis and Bidding from Weeks to Hours

AI-driven platforms are no longer a theory—they’re now standard tools on the desk of ambitious project managers, cost estimators, and contractors. At this early, decision-heavy stage, AI tools help us:

- Automate quantity takeoffs and cost estimating by examining digital plans and historical data, often reducing these tasks by up to 90% compared to manual methods.

- Generate smarter schedules that adapt to weather forecasts, labor availability, and material lead times, making project plans more dynamic and fewer delays catching teams off guard.

- Increase bid volume and accuracy: AI lets us confidently bid more projects, knowing estimates are grounded in data across thousands of variables, rather than guesswork or outdated benchmarks.

With tools like ConstructionWire, for example, we’re able to arm project teams with up-to-the-minute details about current and planned construction opportunities, decision-maker contacts, and even market alerts. This tight integration of data and AI helps stakeholders make more thoughtful, informed moves—faster.

Real-Time Project Optimization: AI Moves Beyond Scheduling

AI is not just for planning. As the first shovel hits the ground, real-time data feeds and predictive analytics step in to constantly optimize workflows, site logistics, and crew assignments. For instance:

- Sensor-driven monitoring (think computer vision and IoT sensors) keeps tabs on material deliveries, worker safety compliance, and actual work progress relative to plan.

- Instant alerts flag deviations, allowing proactive course correction (not just reactive damage control).

- Dynamic rescheduling—If rain halts concrete pour, AI platforms can instantly shuffle resources, adjust supply deliveries, or bring forward alternative tasks so the project doesn’t grind to a halt.

By centralizing these insights with construction management tools such as Pantera, we give project teams a live dashboard of what matters most, keeping effort focused on high-impact activities and eliminating administrative drag.

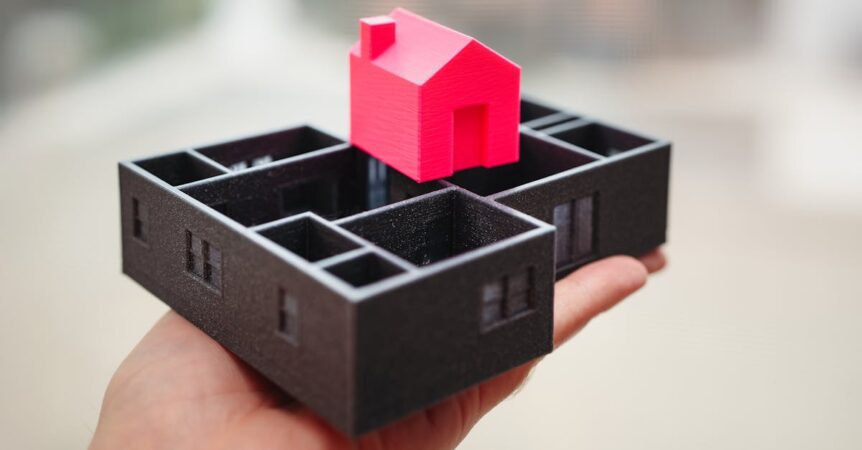

3D Printing: Taking Off-Site Fabrication to the Next Level

3D printing isn’t just a buzzword—it’s being deployed on jobsites and in controlled environments to produce structural components, facades, and even entire small buildings. Here’s why it’s a game changer for timelines:

- Continuous building: 3D printers can run 24/7, producing walls and modules in hours or days compared to weeks by traditional crews.

- Precision with less waste: Material usage is programmatically controlled, virtually eliminating rework and excess. This reduces both time spent handling waste and the cost of overordering supplies.

- Off-site manufacturing: Custom elements can be printed off-site and delivered ready for rapid assembly, taking unpredictable weather out of the critical path.

For example, in one widely-noted project, over 70% of a home’s main structure was printed in less than two weeks—highlighting the leap from months to days that can be possible for certain designs.

The AI + 3D Printing Combo: Self-Optimizing Construction

Where these two technologies intersect, we see real acceleration:

- AI-powered quality checks during 3D printing ensure deviations are caught immediately, reducing the need for rework and saving both time and materials.

- Print path and mix optimization: AI fine-tunes the printer’s sequence and material composition to adapt to site-specific conditions (like temperature and humidity), avoiding delays from poor curing or settings errors.

- Adaptive scheduling: Software coordinates the printing process with site trades, supply chain deliveries, and regulatory inspections, minimizing laydown time and syncing all aspects of the build.

What Kind of Time Savings Are We Actually Seeing?

Based on published results in both residential and infrastructure projects:

- 3D printing can cut project duration by up to 70% for suitable structures.

- AI-driven preconstruction and project management compress key tasks from days or weeks to hours.

- In projects combining these approaches, total timeline reductions of 30-60% are now common, especially for repeatable, modular designs.

The precise savings depend on project size, complexity, and design adaptability, but even the most conservative adopters are seeing weeks, if not months, disappear from schedules.

Best Practices: How to Start With AI and 3D Printing

- Identify Projects Suited to Automation: Focus on builds where standardized elements or modular components are prominent. These are ideal for 3D printing and allow AI-driven management to demonstrate full impact with fewer variables.

- Leverage AI-Enabled Bid and Permit Platforms: Platforms like QuestCDN and Construction Monitor can quickly connect you to public bid opportunities, permit insights, and real-time project alerts, shrinking wait times between project phases.

- Update Design Processes: Work closely with architects and engineers to ensure digital blueprints are optimized for both AI analysis and 3D printing compatibility right from the start.

- Integrate Sensors and Analytics: Use real-time data feeds to monitor materials, progress, safety, and site utilization. This enables instant responses when things veer off track, instead of expensive catch-up efforts.

- Strengthen Procurement With Digital Tools: Time lost to manual procurement can be regained through eTendering and supplier management solutions like NAPC. This keeps material delivery in sync with robotic and 3D printing schedules.

- Iterate and Refine: After each AI- and 3D-enabled project, gather time, cost, and process feedback to further compress schedules in future builds.

Enabling Data-Driven Acceleration: Our Approach at Hubexo

We see our role as more than data providers—we’re enablers of true construction transformation. Here’s how our integrated portfolio ties the acceleration promise of AI and 3D printing to tangible results:

- Integrated market intelligence and project info: BidOcean and ConstructionWire let clients and teams act on the latest pipeline, permitting, and stakeholder data in near real-time, expediting both planning and execution.

- Centralized management and analytics: Pantera’s field-to-office platform ensures every adjustment (no matter how minor) is synchronized across the team, keeping all trades aligned as changes occur.

- Guided product and material selection: Product Intelligence provides designers and procurement leads with not just vendor data, but actionable insights into specification trends—vital when sourcing for print-compatible projects.

- Seamless bid and procurement automation: QuestCDN and NAPC help move projects from intent to contract in record time, automating compliance and administrative steps that used to pile up in the inbox.

By leveraging these platforms hand-in-hand with state-of-the-art automation and printing, our clients aren’t just shaving days—they’re changing the baseline for what speed and quality can mean in construction.

The Future Is Fast, Coordinated, and Data-Driven

Looking ahead, the construction sector is poised for even greater acceleration as AI and robotics mature. We’re beginning to see cities and governments prioritize these digital workflows, as labor constraints, urbanization, and sustainability imperatives increase pressure to build both faster and smarter.

Our message is simple: The earlier you bring AI-powered analysis and 3D printing into your workflow, from preconstruction through handover, the sooner you’ll see dramatic reductions in project delivery times—and fewer of the headaches that come with traditional build models.

Ready to Accelerate?

We’re proud to be a partner for organizations committed to working at the new pace of construction. If you’re considering integrating AI or 3D printing into your next project—or simply want to understand what’s possible with data-driven tools—we’d love to help illuminate your next steps.

Learn more about our complete platform and how we’re helping construction teams worldwide move from delay-prone to deadline-crushing. Visit Hubexo to see how we’re helping the world build better, faster, and smarter.